Thermostatic Wax Valve Actuators

The wax-filled thermostatic element was invented in 1936 by Sergius Vernet (1899-1968). Designed to transform heat energy into mechanical energy using the thermal expansion of waxes when they melt, its first application was in automotive thermostats used in the engine cooling system. Thermostatic wax valve actuator uses have expanded into heating systems, plumbing systems, industrial equipment & systems, and aerospace & defense applications.

The unique quality of paraffin wax, and the reason that it sits at the heart of each of our temperature control valves, is that it is predictable. When exposed to variations in temperature within its active range (typically 10°F), the performance of the thermostatic element can be predicted with a relatively high degree of accuracy.

The operation of a thermostatic actuator is based on the principle that there is a significant change in the volume of paraffin wax as it goes through a phase change from solid-to-liquid; liquid-to-solid as the wax temperature increases and decreases.

Transforming Temperature Variations into Motion

Inside each of our thermostatic valves is a paraffin wax valve actuator filled with our proprietary Thermoloid® blend of precisely mixed ingredients. The actuator blend is designed to give a controlled volume change, and hence known stroke response, within a narrow range of temperature variation.

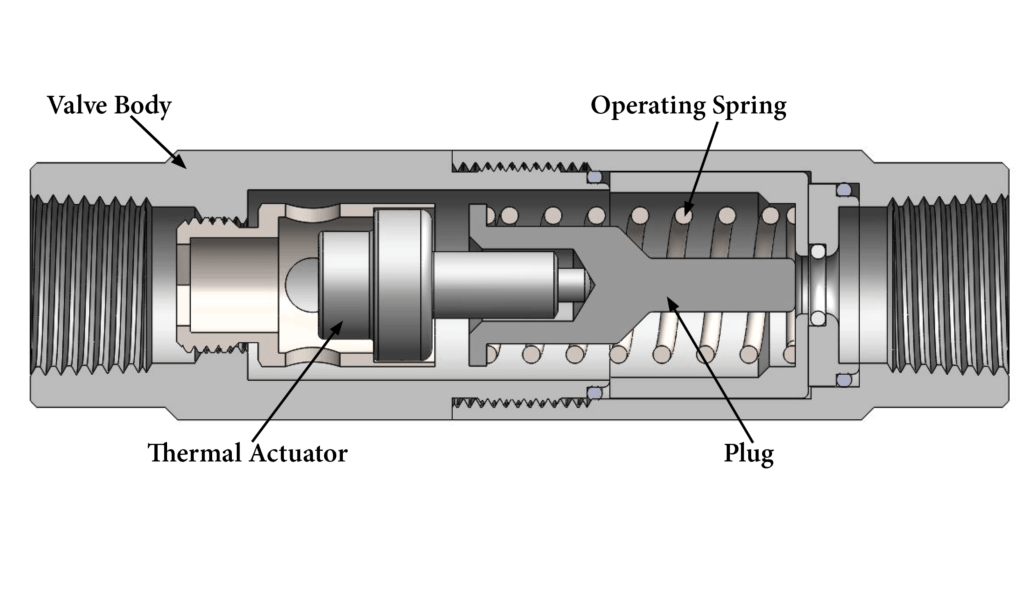

Each of our valves include the Thermoloid® pellet (the expansion-producing element), a diaphragm to seal the wax and help transfer the expansion of the pellet, a plug which amplifies the wax expansion and transforms it into linear motion, and a piston which produces useable stroke.

When the actuator is in its “cold position” the Thermoloid® wax is solid, and the piston is retracted. Once the temperature increases to within the wax’s active range, the wax changes into its liquid phase, undergoing thermal expansion and increasing in volume. This expansion extends the piston, putting the actuator into its “hot position.” The piston can then act upon a valve stem, lever or any other mechanical device requiring this type of movement.

This thermal phase change in the active region and resulting piston motion occur over a narrow and customizable temperature range – typically within 10-15°F. The precise temperature range varies depending on the chemical composition of the Thermoloid® material used.

The wax can be blended to change phase within a specified temperature range to meet the required characteristics of an application in order to convert changes in temperature into mechanical motion. In addition, due to the incompressible nature of the wax and its high density to size ratio, the motion produced generates a significant amount of force.

Benefits of Thermostatic Control

ThermOmegaTech® offers a myriad of thermostatic control valves to satisfy temperature control needs in both heating and cooling applications. The simplicity of the paraffin wax valve actuator lends to its versatility, arguably the most ingenious benefit of our precise thermostatic temperature control valves. Notable advantages of implementing thermostatic technology do not end there and include:

- Self-Actuating: Transforming temperature variations into motion, Our valves eliminate the need for an external power source

- Maintenance-Free: No periodic calibration – you can trust that the valve you install will continue to operate as it should through its service life

- Highly Repeatable: The properties of our Thermoloid® wax are so precise that they are used as primary reference standards by ASTM for instrument calibration

- Few Moving Parts: Simplicity of design increases service life and minimizes potential part failures

- Long Service Life: Rely on our valves to precisely control your system for years to come

- Compact: A high power to size and weight ratio makes for small, light-weight packages, ideal for A&D applications where size is often at a premium

- Unaffected by Extremes: Pressure changes do not affect our temperature control actuators ability to phase change, making them ideal for applications in hazardous environments

With the intrinsic accuracy of phase-change modulating valves to account for gradual temperature changes, as opposed to complex open/closed control valves, the applications for our technology are limited only by the designer’s imagination.

Thermostatic vs. Solenoid Valves

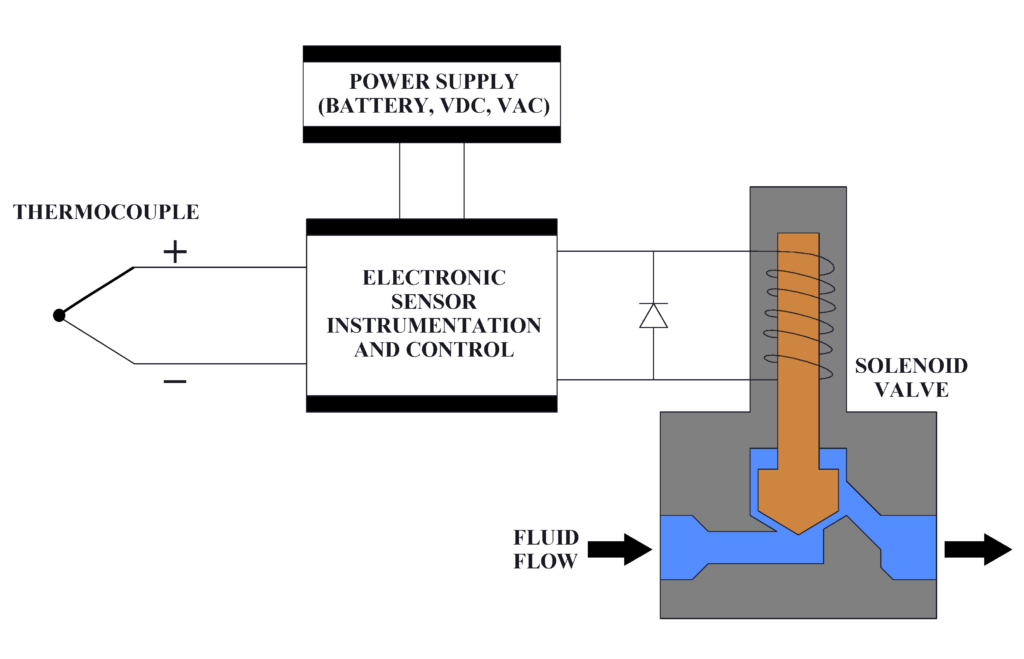

Thermostatic valves are entirely self-powered – the “wax motor” at each valve’s heart phase changes in response to temperature variations, prompting a thermal expansion or retraction that moves a piston to precisely control system flow. Our valves do not need an external transducer or power source. In addition to often being the sole or primary thermal control component, it can also be used as a last line of defense for externally powered devices to ensure continued actuation in the event of total power failure. Since power is not required, thermostatic valves are ideal solutions for applications in explosion-proof environments.

Traditional externally powered “electronic sensing” solenoid valves are complex wiring of components, often including temperature sensors, an amplifier, control electronics, the solenoid valve itself, and a source of DC power. This elaborate setup lends to additional installation expenses, increased space requirements, and potentially disastrous results for delicate systems should power be lost.

In addition to increased thermal precision associated with gradual phase-changing wax actuators, thermostatic control valves provide substantial cost savings by virtue of their design:

- No additional components are required for the valve to operate, significantly reducing both installation and operating costs

- Temperature regulation, fluid control for open or closed loops, and positioning modulation are contained within the valve body, eliminating maintenance and part failure expenses.

- With no need for an external power source to operate, a temporary or prolonged facility power failure will not affect the valve or the temperature-sensitive system it maintains

Precise, compact, and reliable thermostatic valves are the preferred temperature control solution that can be trusted in delicate Aerospace & Defense applications.

Thermostatic Valve

Solenoid Valve

Standard & Custom Valve Design

Thermostatic wax valve actuator technology is incredibly flexible; its parameters can be molded to fit your unique temperature control project and individual vision.

Our in-house team of experienced, multi-disciplinary engineers have designed dozens of innovative temperature control solutions for Aerospace & Defense applications. In addition to our comprehensive catalog of standard products for thermal bypass, electronics cooling, airflow control, freeze protection, scald protection, and more, we offer custom-design engineering services to satisfy unique product requirements.

Schedule a Lunch & Learn consultation with ThermOmegaTech’s® product specialists and design engineers to discuss your temperature control needs.