7 Reason to Choose Thermostatic Control For Mission Critical Applications

Thermostatic Control Valves Vs. Solenoid Valves

When it comes to system performance in mission-critical aerospace and defense applications, thermal control is a leading factor in successful operations. Having an effective flow control device to balance temperature within the system ensures a more efficient and stress-reduced operation. There are two commonly implemented types of flow control valves for A&D applications, solenoid valves and thermostatic control valves.

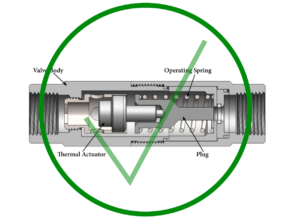

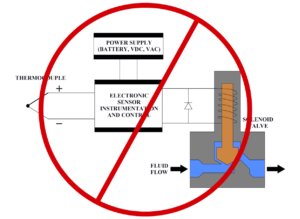

Solenoid valves require a complex set-up with multiple components external to the valve, as well as a source of DC power to operate which tends to increase installation expenses, space requirements, and the risk of operation failure in the case of a power outage or component failure. ThermOmegaTech recommends thermostatic valves as the #1 thermally controlled flow solution for A&D applications. Precise, compact, and reliable, thermostatic valves are entirely self-powered and respond to narrow temperature variations to precisely control system flow, without the need for an external power source. Thermostatic valves automatically respond to temperature changes and self-adjusts to achieve and/or maintain a desired temperature for a process or equipment. Simplistically designed, thermostatic valves can be located virtually anywhere, and used as a main source or used for back-up/fail-safe operation. Notable advantages of implementing thermostatic technology doesn’t end there though: To learn more about the differences in these types of valves check out our comparison sheet.

Thermostatic Control Valves

Solenoid Valves

7 Major Benefits of Thermostatic Valves